All wood floors start with a tree. The pattern of your hardwood floor depends on the species of tree the wood comes from. You may think that’s all there is to it, but there’s another factor that affects the look of the wood grain as well – the way it’s sawn. The way the logs are sawn will have a striking impact on the look of the boards that are harvested.

Related Read: Wood Floor Trends to Watch for in 2017

Cutting Methods for Creating Wood Planks

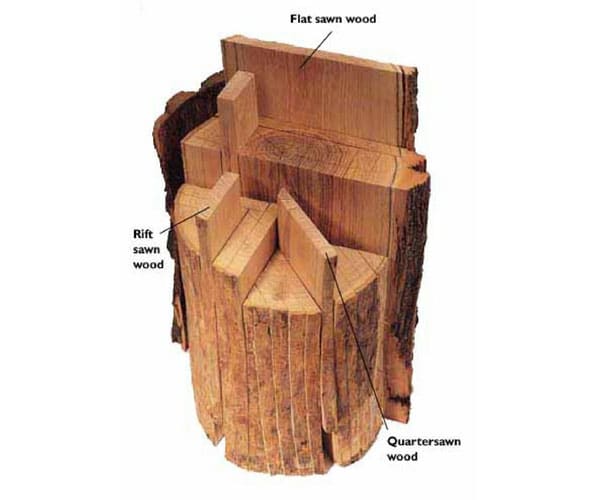

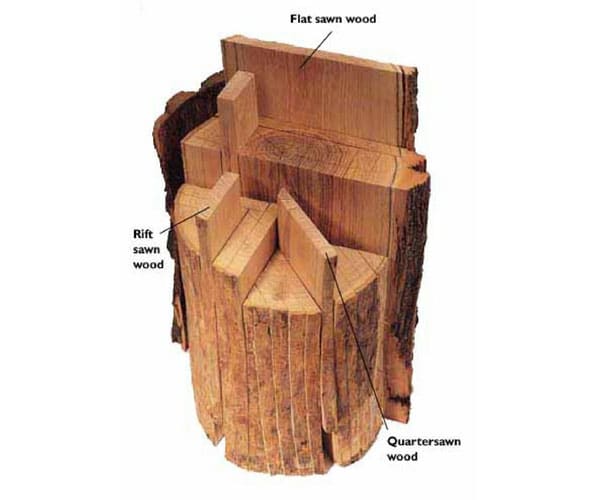

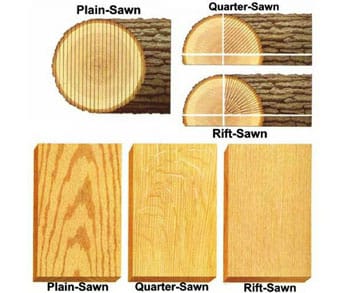

There are basically three common methods of sawing boards from a log:

Plain Sawn

This is the most common sawing method. The pith is the center or core of the log. Plain sawn boards are cut parallel to the pith on four sides.

Every board sawn this way will have a unique appearance with various color and pattern designs than boards sawn using other methods. The wood grain is the star of plain sawn boards.

Quarter Sawn

Quarter sawn boards start by sawing the log into equal quarters (picture an X in the center of the end of the log.) Then each quarter is sawn along the flat sides, cutting through the growth rings at about a 90 degree angle. This method produces fairly uniform boards with similar grain patterns.

Rift Sawn

Rift sawn boards are created when the last part of the quarter sawn boards are cut. Rift sawn boards are differentiated by the fact that the growth rings on the outer edge of the log are different from those nearer the pith. The grain on the top of the board will be linear, but if you look at it from the end, the grain will be more slanted.

Cutting Methods for Creating Veneers for Engineered Wood Floors

Engineered wood floors are popular as well. There are basically two types of hardwood floors – solid and engineered. Solid hardwood planks are one solid piece of wood from top to bottom and end to end. Engineered hardwood planks are made by stacking multiple layers of wood together in various directions and binding them into a solid form with heat and pressure.

A thinner hardwood veneer is glued on top and that is the part of the floor that is seen. Engineered hardwood floors are very popular in lower levels and areas where moisture or humidity might be a factor as they don’t warp like solid wood will.

Related Read: Avoid the Pitfalls of Installing a Wood Floors in a Finished Basement

Dry Sawn vs. Rotary Peeled

Two different sawing methods are used to create the veneer on top of engineered wood planks – dry sawn and rotary peeled.

Dry Sawn Veneers

Dry sawn veneers are hardwood planks sawn in the desired thickness of the veneer. They retain the natural grain look of solid hardwood flooring. Each board is unique with no repeating patterns. Depending on the thickness, it can be resanded three to five times.

Rotary Peeled Veneers

With rotary peeled veneers, the log is boiled and then peeled in ultra thin layers using a rotary cut. This is the same method used to make plywood and it creates a repetitive pattern similar to plywood. Because it is so thin, usually only one sanding, if any, can be performed over its lifetime.