Hardwood flooring is a great choice for any home. Not only does it look great, it lasts for decades, and adds value to your investment. It even improves resale appeal and asking price. But once you’ve decided on hardwood floors, there are some other decisions you have to make. At SVB Wood Floors, we walk our customers through these decisions all the time, so we thought we’d put together a little walk-through of the process to make it easier. Here are some considerations:

Table of Contents

Consider Functionality First

What are you using the room(s) for? Do you need extremely durable wood? Do you need moisture resistance? Are you thinking of adding radiant heat? Would you like the option to refinish at a later date? What about cleaning and maintenance? We have a wide variety of hardwood floors to choose from and knowing the answers to these questions will help narrow down your choices.

Solid Vs. Engineered Wood Flooring

Solid hardwood is made from thick, solid planks of wood that are joined with a tongue and groove along each side. Some people prefer authentic solid wood. These floors can be sanded and refinished multiple times because they are solid wood all the way through. They will literally last a lifetime with proper care.

Engineered wood floors are made with a thin veneer layer of real hardwood on top of multiple layers of composite material and plywood. While they are not solid wood, the many layers add stability and keep the flooring from shifting over time or warping with moisture. However, because they only have a thin veneer of wood floor on top, depending on the wear layer, you may be able to refinish multiple times or not at all.

Prefinished Vs. Unfinished

When you purchase new wood floors, you can order them prefinished or unfinished. Here are some of the pros and cons of both:

Prefinished Hardwood Flooring

When you order prefinished hardwood floors, you know exactly what they will look like. The stain and topcoat are applied in a factory and are usually flawless because of the controlled conditions. Prefinished floors are also faster to install because there is no sanding or finishing involved. Once they are nailed in, they are good to go. Some say the seams are more noticeable in prefinished floors as they have a bit of a bevel to the edges of the boards vs. unfinished planks, so make sure to pay special attention to that. Prefinished flooring can be less expensive because it is faster and easier to install.

Unfinished Flooring

Unfinished floors (sometimes called site finished) will come to your home raw and unfinished. The planks are installed, then sanded, stained and finished in place. Unfinished floors allow for more customization. You can choose the color of stain and level of sheen (matte to glossy and anywhere in between). If you are trying to match a new floor to existing wood flooring in your home, unfinished is the way to go. Site finish floors can often have a smoother appearance.

Dustless Sanding

Sanding wood floors before finishing them is a necessary step that used to be extremely messy and inconvenient, spreading dust throughout your home and forcing homeowners to vacate until the job was finished. With SVB Wood Floors, you don’t have to worry about any of that because we provide dustless refinishing.

Our dustless sanding system, by Bona, eliminates the mess completely. The Bona Atomic Dust Containment System®, or DCS, traps all airborne dust before it can spread throughout your home and transports the particles into an Atomic DCS® trailer outside. Dust never has a chance to escape into your home or ductwork and there’s no need to board pets or move out of your home.

Staining Options

Choosing a stain can be the most stressful part of the process for some homeowners. At SVB, we make it easy. First, we use the highest quality Duraseal stain colors. We have many beautiful pre-mixed stains, but with our ability to mix and match them, we can create the exact color you choose with our custom color process. We always arrive with every stain color we offer on hand. Once you have chosen a few, we test them directly on your wood floors to compare them side by side. Seeing the stain colors on your actual floor can help narrow down what you are looking for. Plus, you can compare them to existing items like cabinets and woodwork around windows. Learn more about our custom stain process.

Finishing Options

Once your floor is stained, it’s time for the finish. The finish will protect your floor from everyday traffic and keep it looking good. At SVB Wood Floors, we use three coats of an environmentally safe, durable and fast-drying top coat. The first coat seals. The second and third coats build thickness for years of durability. We screen, buff, and vacuum between coats for the absolute best finish. You can choose from a matte finish to a high gloss finish or anything in between.

Plank Width

Hardwood flooring planks come in a variety of sizes. Planks typically range from 2-3 inches wide to 7 or 8 inches wide. Wide plank flooring shows more of the wood grain, knots, and other details that some people find attractive. With wider planks, there are fewer seams, but conversely, the seams may be more noticeable in the winter and over time as the boards have more room to shrink when the humidity is lower. Wider planks are also more expensive.

Wood Species

There are many different species of wood and each one has different qualities – texture, color, hardness, etc. From ash to oak, cherry to walnut, how do you decide? Here is a quick guide to some of the most common species along with their traits to help you decide which one is right for you and your home:

- Oak (hard, medium colored, distinctive grain pattern featuring waves of brown and beige dotted with small areas of black)

Durable and affordable. Good for kids and pets

- Hickory (hard, dense, and shock-resistant with a coarse, straight grain)

Durable. Good for high-traffic areas.

- Birch (strong, durable, ranges from reddish-brown heartwood to almost white sapwood)

Affordable and eco-friendly

- Cherry (hard, reddish hue, darkens with age)

Hues vary greatly, so wider planks provide better uniformity of color

- American Black Walnut (softer, darker, intricate grain pattern)

Good for low traffic areas like dens and bedrooms

Of course, there are dozens of wood species and they are available in different plank widths as well. Click here to learn about the different species available. At SVB, we have a beautiful showroom with samples of everything and we can walk you through your options in a stress-free setting.

Textures

While wood species vary in color and hardness, most hardwood floors have a fairly similar, smooth texture. But if you’re looking for something unique to set your home apart from the others, consider distressed, hand-scraped, or wire brush finished wood. Handcrafted flooring provides variations in texture that cannot be replicated in a factory. Each and every board is hand scraped which ensures that no two boards are ever alike. True handcrafted flooring allows you to dictate the type of wood, plank widths, lengths, and, of course, the level of scraping and hand finishing you desire. Handcrafted wood floors complement rustic homes perfectly and provide results that are unsurpassed in terms of quality, uniqueness, and beauty.

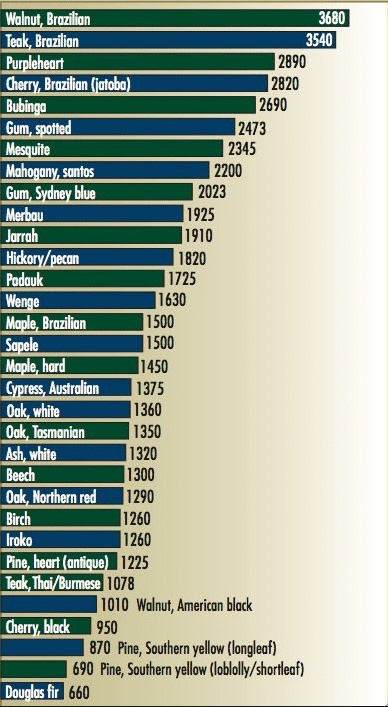

Hardness

The hardness of a wood is rated on an industry-wide standard known as the Janka scale. A Janka rating of 1,000 or higher will provide good durability. Here is an example of the Janka Scale from the NWFA (National Wood Floors Association) website.

The hardness of a wood is rated on an industry-wide standard known as the Janka scale. A Janka rating of 1,000 or higher will provide good durability. Here is an example of the Janka Scale from the NWFA (National Wood Floors Association) website.

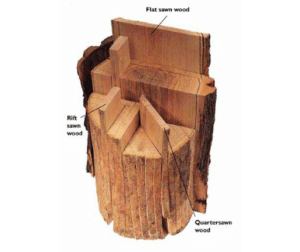

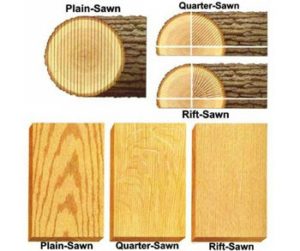

Grain Pattern

Many people don’t realize it, but the way a piece of wood is cut will create a unique grain pattern on the planks of wood. Plain sawn is the most common cut you see, probably because it is the most visually appealing, but there are two other ways to cut planks – rift sawn and quarter sawn. The visual below shows how these cuts differ.

Plain Sawn

This is the most common sawing method. Plain sawn boards are cut parallel to the pith (center). They have a unique appearance with various color and pattern designs. The wood grain is the star of plain sawn boards.

Quarter Sawn

Quarter sawn boards start by sawing the log into equal quarters. Then each quarter is sawn along the flat sides, This method produces fairly uniform boards with similar grain patterns.

Rift Sawn

Rift sawn boards are created when the last part of the quarter sawn boards are cut. wood has a long and consistent grain but no cathedrals. Plain sawn wood is the most common and most popular. It has a traditional wood grain with patterns called cathedrals.

Here is what the planks look like when cut with each technique:

Click here for more details about the way wood is cut. If you like a certain look, make sure to let us know so we can find the manufacturers who have that look and steer you in that direction.

We realize this is a lot of information regarding wood floors, but don’t worry. You can visit our showroom and see all of your choices up close and in person. You can even take home samples to compare in your home. From our in-home consultation to our custom stain colors, we make sure all of your questions are answered and you get exactly what you want.

At SVB Wood Floors, we are proud of our reputation for excellence. From the in-home wood floor design consultation to the time we walk out your door, you can expect prompt, courteous, helpful people every step of the way. We make the installation process easy and painless too. When we are working in your home, we take great care to use floor coverings, shoe covers, and to always leave the workspace cleaner than we found it. You will also appreciate our clear communication throughout the whole project so you always know when to expect us, when we will be finished, and who you can turn to for any questions.